/

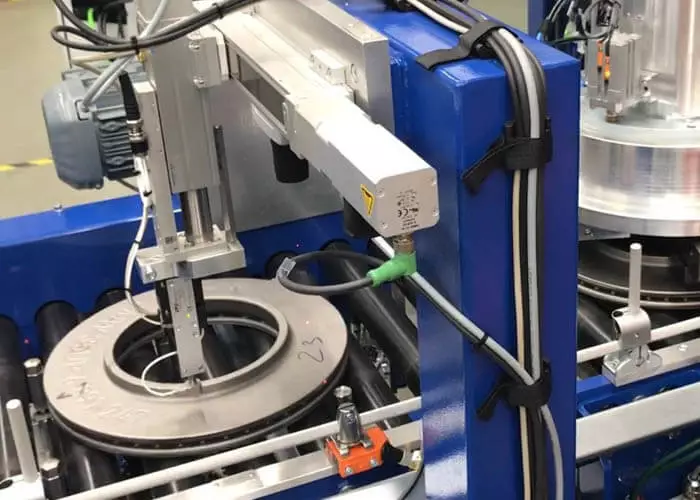

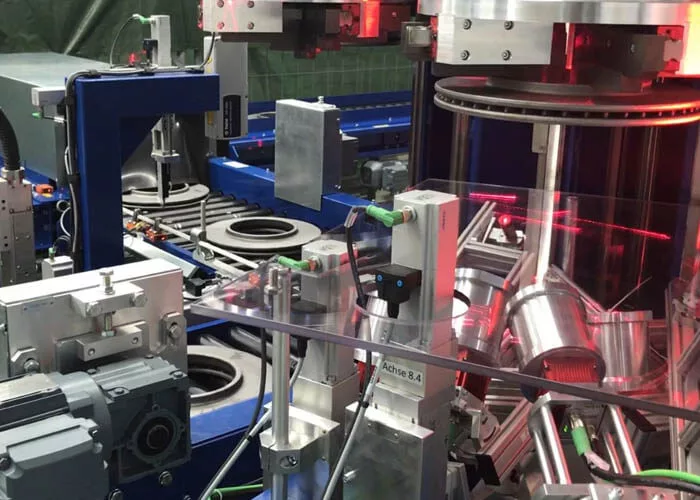

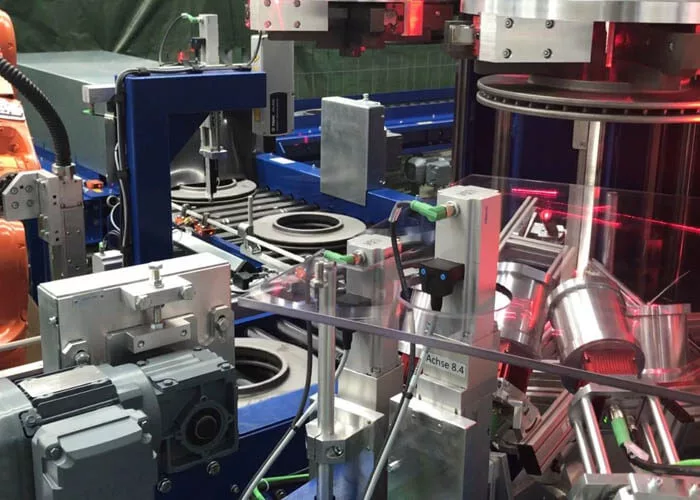

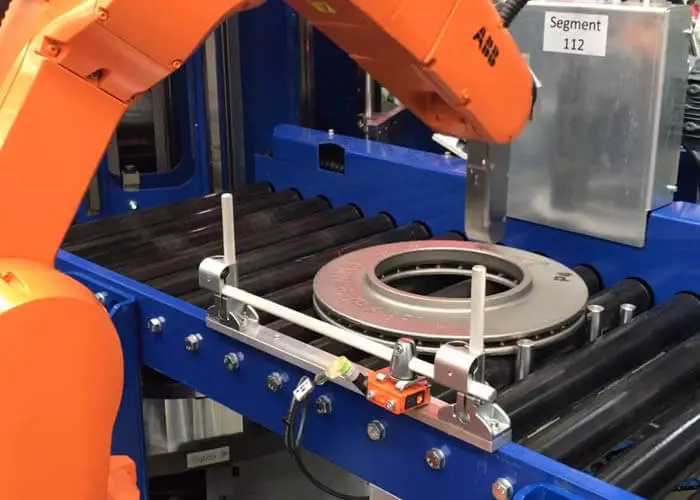

Lives depend on brake disks. They must therefore be 100% tested in the initial inspection after casting.

We have cleverly automated this process of circumferential testing and solved the complex task of measuring even the finest channels with the perfect combination of good, solid mechanical engineering and state-of-the-art testing technology. Your advantage: An absolutely reliable 100% check of all relevant areas in 3.5-second intervals. Only MATHEUS does this. 100% security.

The Matheus automated brake disk initial inspection includes

We need your consent before you can continue on our website. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.