/

With robot-based tire assembly, MATHEUS has developed a completely new automation option for a process that was previously only possible manually.

The unbeatable advantage: Thanks to the innovative, patented initial filling under vacuum and other clever ideas, we achieve extremely short set-up times. Different tire sizes and models can be filled one after the other without manual set-up and time delays. This makes you more flexible and saves enormous costs in the long term. Especially for smaller quantities and frequently changing tire types. 100% clever.

Your benefits with robot-assisted tire fitting from Matheus

The rims are fed into the system via pallets, depalletized and fed into the assembly station via a turntable.

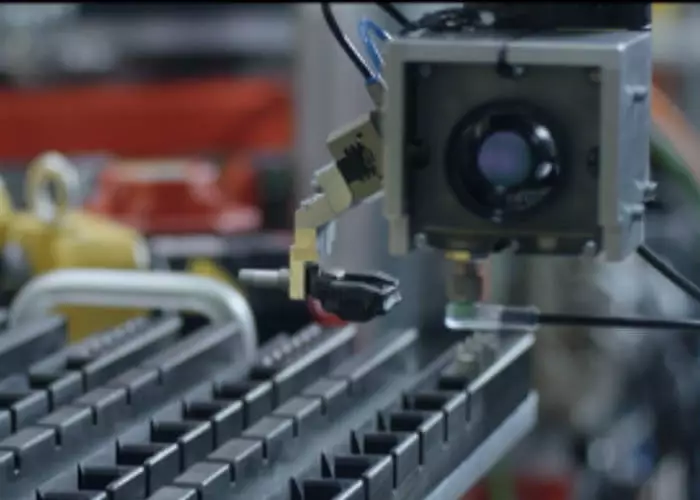

The valve is fed flexibly from the magazine.

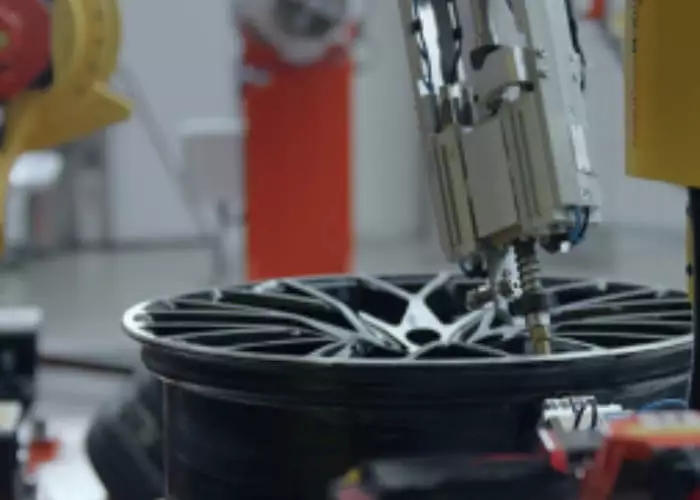

The tires are then optimally positioned on the rim and automatically fitted with the least possible force.

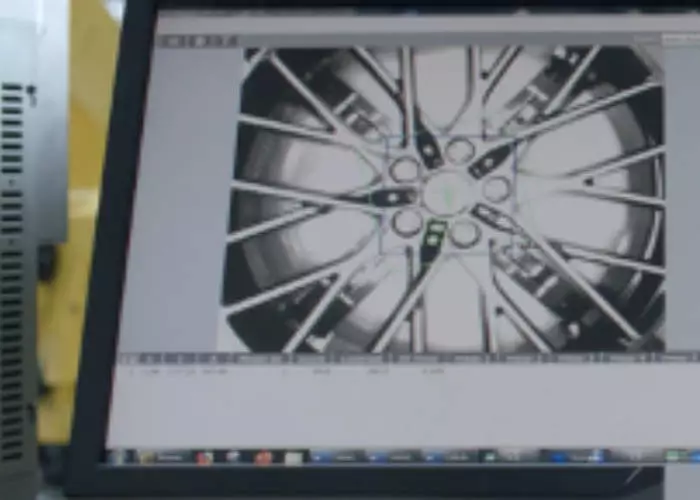

Image recognition systems are used to align the tire correctly with the rim.

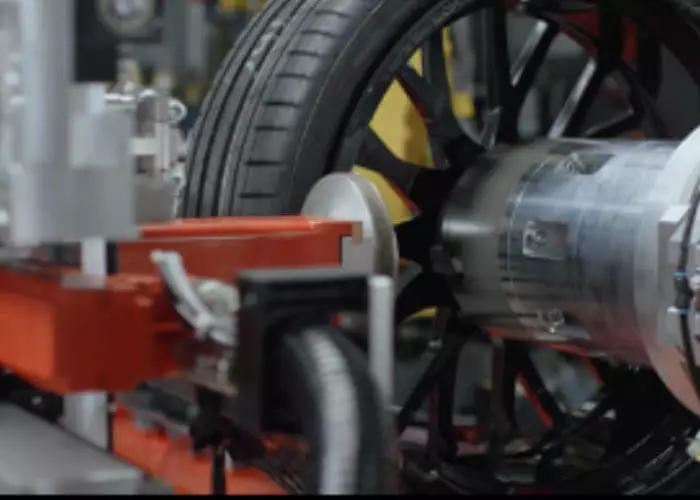

The initial filling of the matched tire/rim combination takes place under a vacuum bell jar. This means that all tire sizes can be fitted in a time-saving manner without conversion.

After inflation to nominal pressure, the optimum fit of the tire on the rim is checked automatically – regardless of tire and rim sizes, different pressures and other variable parameters.

Finally, the finished tires are automatically balanced and transported away.

We need your consent before you can continue on our website. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. Here you will find an overview of all cookies used. You can give your consent to whole categories or display further information and select certain cookies.