for grippers

/ MATHEUS special grippers and gripper systems

/

As the central element of an automated system, each Matheus gripper is precisely tailored to its task and the specific requirements of its environment. Specifically for a single function or as a highly complex solution for a wide range of multiple applications. High quality, reliable and durable. 100% quality.

Gripper development has been a particular focus at MATHEUS since 1992. This experience pays off. In finding the most efficient solution in each case. And in a quality that ensures outstanding reliability, availability and service life.

What should your gripper do?

We develop the right gripper solution for you – as stable as necessary and as light as possible. And perfectly equipped for any operating environment. With alkali-resistant material and specially protected sensor technology when exposed to high pressure, heat, steam and emulsions in cleaning systems. Or for sand core production with specially protected hoses and armed against abrasive material. Always in such a way that it can withstand even the toughest of environments.

This example might interest you

- Loading

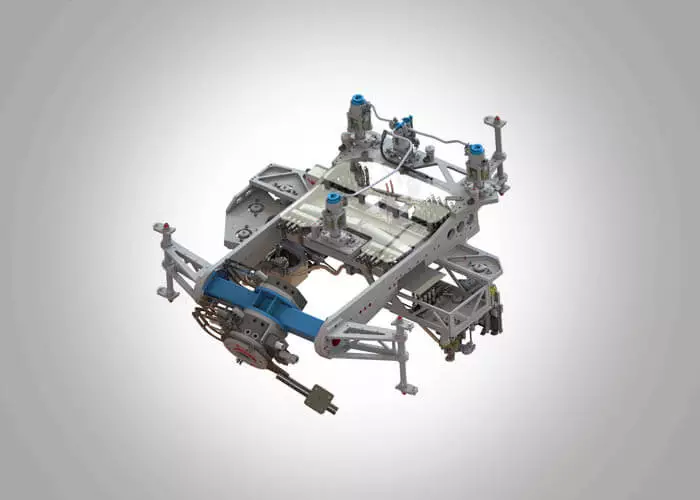

Gripper for loading and unloading machining centers with an integrated vision system and functions for finishing the workpieces after removal from the machine.

- Assembly

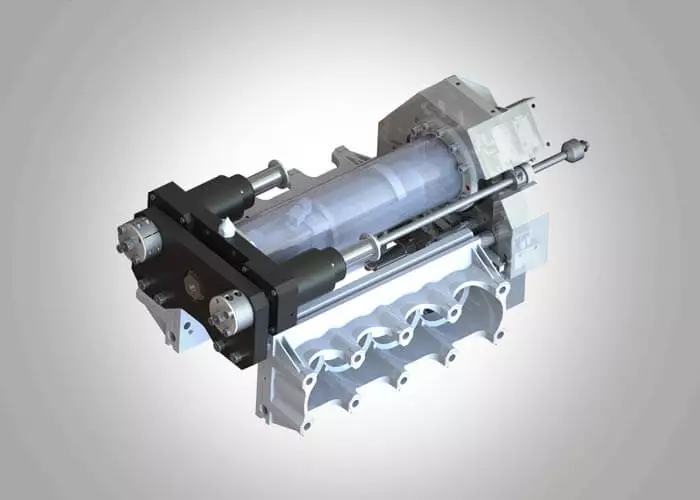

Gripper for passenger car tank production with complex functions for handling complete tanks and assembling internal components.

- Coating

Gripper for the core shop with hermetic seal for dipping the core packs in the sizing tank.

- Cleaning

Gripper for use in high-pressure cleaning systems under the most difficult operating conditions (temperature, cleaning agent, steam, water).